A TRIAC, short for triode for alternating current, is a semiconductor device that can control the flow of current in both directions in an alternating current (AC) circuit. It is essentially two back-to-back connected SCRs (silicon-controlled rectifiers) with a common gate terminal. The TRIAC is commonly used in AC power control applications, such as dimming lights, speed control of AC motors, and temperature control of heating elements.

The operation of a TRIAC is based on the principle of bidirectional conduction, allowing it to control the AC current flow during both positive and negative half-cycles of the AC waveform. Here’s a simplified explanation of how a TRIAC works:

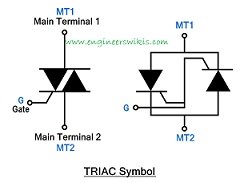

- Structure: A TRIAC is a four-layer, three-terminal semiconductor device with two main terminals called MT1 (Main Terminal 1) and MT2 (Main Terminal 2) and a gate terminal (G). The two SCRs inside the TRIAC share a common anode and cathode.

- Triggering: To turn on the TRIAC , a small current is applied to the gate terminal. This gate current must be positive for the positive half-cycle of the AC waveform and negative for the negative half-cycle.

- Conduction: When the gate current exceeds the threshold level, it triggers the TRIAC into a conducting state. In the conducting state, the TRIAC allows current to flow in both directions between the MT1 and MT2 terminals. This conduction continues until the current falls below a certain threshold level or the AC polarity reverses.

- Commutation: The TRIAC turns off automatically at the zero-crossing point of the AC waveform. At this point, the current passing through the device drops to zero, allowing the TRIAC to naturally turn off. This feature of turning off at the zero-crossing helps reduce electrical noise and prevents abrupt current changes.

- Phase Control: By controlling the timing of when the TRIAC is triggered during each half-cycle of the AC waveform, the amount of power delivered to the load can be regulated. This technique is known as phase control and is commonly used for applications like dimming lights or controlling motor speed.

It’s important to note that the triggering of a TRIAC can cause a small amount of electrical noise due to the sudden change in current. To mitigate this, additional components such as snubber circuits or filters are often used in conjunction with the TRIAC .

The TRIAC’s ability to control AC current flow in both directions makes it a versatile device for many AC power control applications, providing a cost-effective and efficient solution.

What are some common applications where TRIACs are used for temperature control?

Triacs are commonly used for temperature control in various applications where precise regulation of heating elements is required. Here are some common examples:

- Electric Furnaces: Triacs are used in electric furnaces for temperature control. They regulate the power supplied to the heating elements, allowing precise temperature adjustment and maintaining the desired temperature within the furnace.

- Electric Ovens: Triacs are employed in electric ovens to control the heating elements for cooking or baking. They enable accurate temperature control, ensuring consistent and even heat distribution within the oven cavity.

- Induction Cooktops: Triacs are used in induction cooktops for controlling the power supplied to the induction coils. By adjusting the power level, the cooktop can control the intensity of heat generated in the cooking vessel, allowing for precise temperature control during cooking.

- Electric Water Heaters: Triacs find application in electric water heaters for temperature regulation. They control the heating elements to maintain the desired water temperature, ensuring comfort and energy efficiency.

- HVAC Systems: Triacs are employed in heating, ventilation, and air conditioning (HVAC) systems for temperature control. They regulate the power supplied to heating elements, such as electric heaters or heat pumps, to maintain the desired temperature in rooms or buildings.

- Temperature Controllers: Triacs are used in dedicated temperature control devices. These controllers typically incorporate temperature sensors and logic circuits to monitor and regulate the power supplied to heating elements to achieve and maintain the desired temperature.

In all these applications, TRIACs allow precise control over the power delivered to heating elements, enabling accurate temperature regulation. By adjusting the firing angle of the TRIAC , the average power supplied to the load can be controlled, resulting in the desired temperature output. TRIACs are particularly suitable for AC power control, making them a popular choice for temperature control in various industrial, commercial, and residential heating applications.