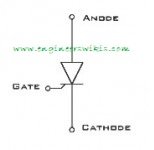

A silicon-controlled rectifier (SCR), also known as a thyristor, is a type of electronic component widely used in power control and switching applications. It is a four-layer, three-junction semiconductor device with three terminals: anode, cathode, and gate.

The SCR operates as a switch that can control the flow of current in a circuit. It behaves like a rectifier, allowing current to flow only in one direction (from anode to cathode), but unlike a regular diode, it can be triggered into conduction by applying a gate current.

When no gate current is present, the SCR remains in a non-conducting state, and only a small leakage current passes through. However, when a positive gate current is applied, it triggers the device into a conducting state, allowing a larger current to flow through the anode and cathode.

Once triggered, the SCR continues to conduct even if the gate current is removed. It remains in the conducting state until the current flowing through it drops below a specific threshold known as the holding current or until the supply voltage is removed.

SCRs are commonly used in applications requiring high-power control, such as motor speed control, lighting control, heating control, and power regulation in industrial equipment. They offer advantages such as high current and voltage handling capabilities, fast switching times, and good thermal stability.

It’s worth noting that while the basic principles and characteristics of SCRs remain the same, there have been advancements in power semiconductor technology since 2021, and newer devices may offer improved performance and additional features compared to traditional SCRs.

What are some common applications where SCRs are used in industrial equipment?

SCRs find numerous applications in industrial equipment due to their ability to handle high-power control. Some common applications of SCRs in industrial equipment include:

- Motor Control: SCRs are used for controlling the speed and direction of motors in various industrial applications. They can regulate the voltage and current supplied to the motor, enabling precise speed control and smooth acceleration/deceleration.

- Heating Control: SCRs are widely employed in heating systems, such as electric furnaces, ovens, and heating elements. By adjusting the firing angle of the SCR, the power delivered to the heating element can be controlled, allowing precise temperature regulation.

- Lighting Control: SCRs are used in lighting systems where dimming or intensity control is required. They enable smooth and efficient control of the light output by regulating the power delivered to the lighting source.

- Power Regulation: SCRs are utilized in power regulation applications to control the amount of power delivered to loads. They are commonly employed in equipment like voltage regulators, power supplies, and power factor correction circuits.

- Welding Equipment: SCRs play a crucial role in welding machines, particularly in arc welding. They help control the welding current and ensure stable and reliable welding operations.

- Uninterruptible Power Supplies (UPS): SCRs are employed in UPS systems to switch between the utility power and battery power during power outages. They facilitate smooth and seamless transitions, ensuring continuous power supply to critical equipment.

- Battery Chargers: SCRs are used in battery charging systems to regulate the charging current and protect the battery from overcharging. They help maintain the battery’s health and extend its lifespan.

- Soft Starters: SCRs are utilized in soft starters to gradually ramp up the voltage and current supplied to high-power motors. This reduces the initial mechanical stress on the motor and minimizes the inrush current, resulting in smoother motor starting.