COMPARISON BETWEEN DCS VS PLC VS SCADA

DCS (Distributed Control System), PLC (Programmable Logic Controller), and SCADA (Supervisory Control and Data Acquisition) are all industrial control systems used in various industries to monitor and control processes. While they serve similar purposes, there are differences in their architectures and applications. Here’s a brief overview of each:

- DCS (Distributed Control System):

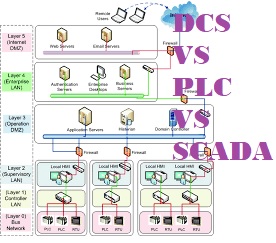

- Architecture: DCS is a control system that consists of multiple distributed controllers connected to a central control unit. The controllers are responsible for managing specific processes or areas, while the central control unit coordinates and supervises the overall system.

- Applications: DCS is commonly used in large-scale industrial processes such as power plants, oil refineries, chemical plants, and manufacturing facilities. It offers advanced control capabilities, robust networking, and high reliability, making it suitable for complex and critical applications.

- PLC (Programmable Logic Controller):

- Architecture: PLC is a digital computer-based control system consisting of a central processing unit (CPU) and input/output modules. It operates using a ladder logic programming language and is designed to control specific machinery or processes.

- Applications: PLCs are widely used in industrial automation and control systems across various industries. They are often employed in applications such as assembly lines, motor control, conveyor systems, and simple to moderately complex processes. PLCs are known for their reliability, ruggedness, and real-time control capabilities.

- SCADA (Supervisory Control and Data Acquisition):

- Architecture: SCADA is a system that combines software and hardware components to monitor and control industrial processes. It typically consists of a central control station, remote terminal units (RTUs) or programmable remote units (PRUs), and communication networks.

- Applications: SCADA systems are used to monitor and control processes in industries such as power distribution, water treatment, oil and gas pipelines, and manufacturing. They provide real-time data visualization, control capabilities, alarms, and historical data logging. SCADA systems often integrate with other control systems like DCS and PLCs to form a comprehensive control solution.

DCS is suitable for large-scale and complex processes, PLCs are widely used for machine control and automation, and SCADA systems are employed for monitoring and control of distributed processes across various industries. While there may be overlaps and integration between these systems, their architectures and applications differs based on the specific requirements of the industrial process at hand.